Details & Specification

This unique and amazing table is capable of automatically doubling its seating capacity whilst remaining truly circular in the process. Expansion leaves are stored within the table and are self positioning as the table changes from one mode and appearance to an entirely different one. Operation, which can either be manual or electronic, is simple and extremely quick.

Electronic tables can easily be converted to manual operation.

Sizes:

The area of the table top expands by 73% enabling each table to have two sizes with varying seating capacities.

We produce three standard sizes of table:

-

1.67 metres to 2.2 metres

(65.7 to 86.7 inches) Chairs 6-8 to 10-12 -

1.90 metres to 2.5 metres

(74.8 to 98.4 inches) Chairs 8-10 to 12-14 -

2.28 metres to 3.0 metres

(89.7 to 118.1 inches) Chairs 10-12 to 14-16

1.67m - 2.2m

6-12

1.90m - 2.5m

8-14

2.28m - 3.0m

10-16

Construction

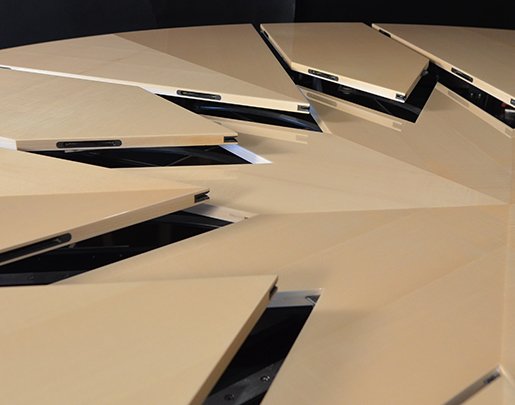

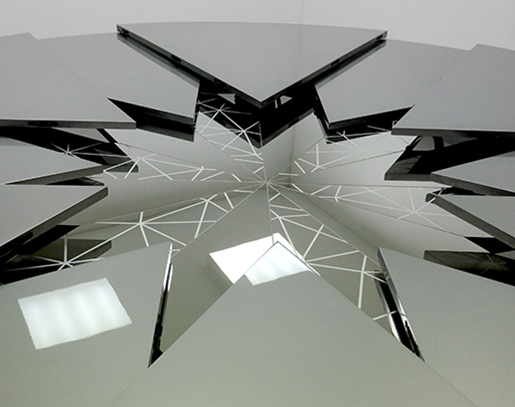

The table top leaves are constructed from a sophisticated layering system and have, at their core, a carbon fibre composite material. This gives them strength, rigidity, stability and low weight.The table top is composed of thirteen self-stored elements and is capable of radial expansion by turning the top through 120 degrees.When small the top is made up of six pie shaped leaves. Under this first layer lie two more layers of leaves, the second made up of six arrow shaped leaves and, under that, a large star shaped leaf.

The small table top is enclosed by an outer skirt in the manner of a drum table.This rises and falls as part of the expansion process and completes the table when it is small, making it truly round in both of its modes.

Beneath these parts lies a complex mechanism constructed primarily from stainless steel and hard anodised aluminium.The materials used are of such high specification that the table is capable of being permanently positioned on an exposed deck of a boat or in a beach house in the tropics. Every component used is of the highest quality and designed to last for generations.

Finishes

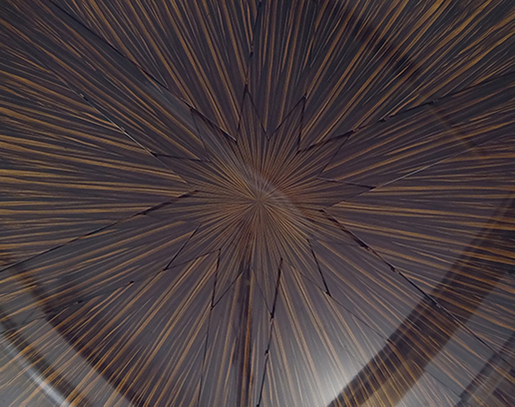

We make tables from any suitable material, but generally speaking from the finest hardwoods available.Teak is frequently selected for marine use, while Brazilian Mahogany or European Walnut are beautiful woods for domestic surroundings. More exotic materials such as Rosewood, Koa and Macassar Ebony can be employed. Or we can use contrasting woods such as Wenge and Sycamore to great effect. We can also offer paint finishes, paint effects and liquid metals.

We can use any form of inlay or marquetry work and sometimes have used burr woods, particularly for the large central star of the table.The geometry of the table lends itself to many other possibilities, so far unexplored. Metals may also be used in the design and the structure of a table.

Our expertise encompasses most types of modern and classic lacquers and oils. We frequently finish in an open or filled grain satin lacquer which can also be applied in such a way that it simulates a French polish, but with more resilient modern advantages. A full gloss finish, with its glass-like appearance, is a popular choice for both residential and marine. For external furniture, we are experienced in all the recognised superyacht grade finishing systems.